Open here for our page navigation

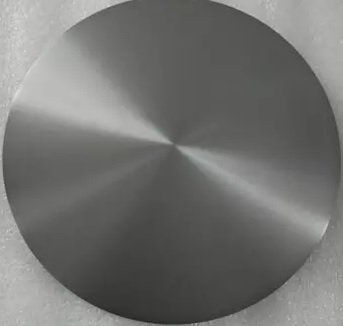

Silicon / Aluminum Sputter Targets, 5 - 10% wt. Al

Purity: 99.9% - 99.9999%

Resistivity: 0.002 - 0.1 Ohm cm

Silicon with Aluminum addition is used for industrial deposition of thin films by sputtering for applications which do not require highest purity of deposition materials (glass coating). The targets from pure Silicon (undoped or Boron doped) may develop cracks as a result of local overheating in the process of DC magnetron sputtering. Addition of Aluminum provides excellent conductivity, uniform heat field distribution, eliminates local overheating and prolongs the target life.

Specification:

Rectangle (diagonal) Disk (diameter) Assembly

Maximum Size: 310 mm (12") 203 mm (8") Not Limited

Surface Finishing: Lapped, Etched, Polished: 2/4 micron (32 / 63 microinch) RMS

Standard Tolerances:

Rectangular Side: +/- 0.10 mm

Disk Diameter: +/- 0.10 mm

Flatness: +/- 0.05 mm

Thickness: +/- 0.05 mm

Diagonal Variation: +/- 0.30 mm

Relationship between Aluminum content and target material Resistivity and porosity:

% Weight of Aluminum Resistivity (ohm cm)(x 10-4) Porosity, (%)

3 5.7 7.8

5 4.0 7.0

7 3.6 6.2

9 3.4 5.0

11 3.0 4.2

13 2.8 3.6

15 2.0 2.6