Open here for our page navigation

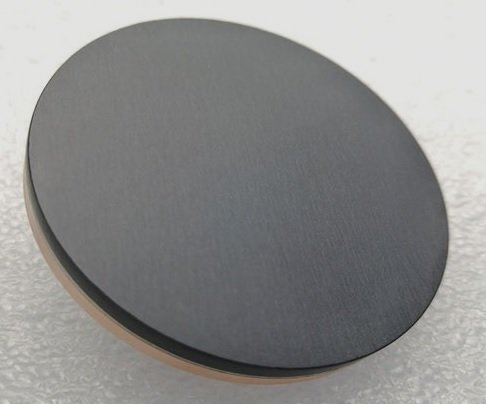

Indium – Tin – Oxide (ITO) Sputtering Targets

(In2O3/SnO2)

Indium Oxide/Tin Oxide (In2O3/SnO2 90/10 wt%,), ITO, is among one of the most popular sputtering target materials used in the thin film industry due to its electrical conductivity and optical transparency.

Specifically, the 90/10 wt%, composition has a melting point of approximately 1,800°C and a density of 7.14 g/cm3. The color of various ITO compounds range from pale yellow to dark green or dark grey.

It is evaporated or sputtered under vacuum to generate transparent conductive layers in the manufacture of LCDs and various optical coatings. Thin films of ITO are created for the development of sensors, as well as, a glass coating for the automotive industry.

Chemical Composition: In2O3 • SnO2 (90:10 wt%,)

Color: Black

Purity: > 99.99%

Relative density: better than 99.2%

Resistance: 1 x 10-4 Oh-cm

Coefficient of Thermal Expansion (CTE): 8 x 10-6 / K

Sputter: RF, DC

At present, the planar target still dominates the sputter coating industry due to its multiple advantages such as simple structure, strong versatility, and good uniformity. However, the utilization rate of a planar target is low.

Recently, sputtering target manufacturers are actively researching and developing a new type of sputtering target (such as the rotatory target) to achieve a higher utilization.

Purity: 99.9%, 99.95%, 99.99%

Shape: Disc Targets, Plate Targets, Column Targets, Step Targets, Custom-made

Size:

Circular: Diameter < 14 inch, Thickness > 1mm

Rectangular: Length < 32 inch, Width < 12inch, Thickness > 1mm