Open here for our page navigation

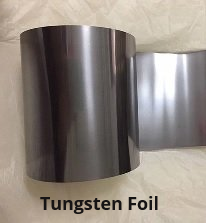

Tungsten Foil

99 - ≥ 99.95% pure

Tungsten foil is produced by cold rolling the tungsten sheet to a lower thickness. The stamped and drawn foil is very suitable to use in the applications of high temperature vacuum furnace, coating, electronics and semiconductor components. Tungsten foil is used to make heat shielding, heating element and carrier of the vacuum furnace. It is because tungsten foils process a high heat resistance in the high temperature environment.

In addition, tungsten foil owns an extremely Low Vapor Pressure and a high melting point so that it is ideally served for coating application as the evaporation boat. Moreover, the ideal material for semiconductor needs to have a Low Coefficient of Thermal Expansion and Low Electrical Resistivity. Tungsten can meet these requirements. Therefore, it is a very suitable material for components of the semiconductor industry. Tungsten has been also approved to be a promising material to explore in further in medical and Sputtering applications.

CAS# 7440-37-7

Atomic Number 74

Atomic Weight 183.85

Density 19.3 gm/cm3

Melting Point 3410oC

Boiling Point 5900oC

Electrical Resistivity 5.65 microhm-cm @ 27oC

Thermal Conductivity 1.73 W/cm/K @ 298.2 K

Electronegativity: 1.7 Paulings

Specific Heat: 0.0317 Cal/g/K @ 25oC

Heat of Vaporization: 185 K-Cal/gm atom at 5660oC

Heat of Fusion: 8.42 Cal/gm mole

Available thicknesses: 0.01 mm to 2.0 mm

Foil dimensions: 25 mm x 25 mm, 50 mm x 50 mm, 100 mm x 100 mm

Strip lengths to: 24 inch (609 mm) long

We also offer Tungsten Heavy Alloy and Tungsten Copper along with other Alloys.